Horizontal RAM extruder

Horizontal RAM Extruder

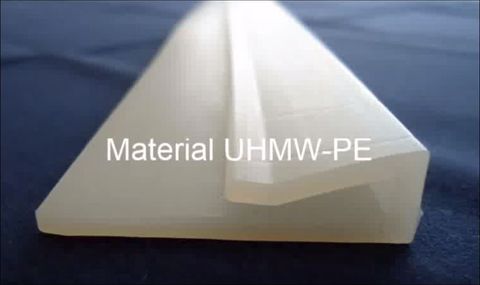

World-class solution for UHMW-PE technology

Our UHMW-PE RAM Extruder The brand name is GUR

Ram extrusion is a pressing process that allows the continuous production of profiles. Specially made of UHMW-PE (ultrahigh molecular weight polyethylene). The base material is UHMW-PE powder, which is fed into a cylindrical extrusion tube, compressed by means of a punch and simultaneously transported through the tube, which is heated to sintering temperature. The individual dosing charges sinter together to form a continuous extrudate.

Advantages of the Keicher RAM extruder or PTFE extruder

- Horizontal design for space reduction of the UHMW-PE RAM Extruder

- Short set-up times through easy and quick die change

- Consistently high quality of the products through permanent electrical measurement and precise temperature control

- Uniform and exact dosing through electronic dosing system

- User-friendly and maintenance-free

- Possibility of stepwise expansion to a fully automatic manufacturing system through modular design

- Operation via touchscreen and recording of the exhausion parameter

- Safe operation date

- Automatic adjustin of extruder and heatings according to preexisting recepts

Your direct contact

Should you require additional information about our products