Paste extruder

Paste Extruder

World-class solution for PTFE technology Patented technology which sets new standards

PTFE extrusion process with a PTFE extruder, which is also known as a PTFE paste extruder or only as a PTFE extruder

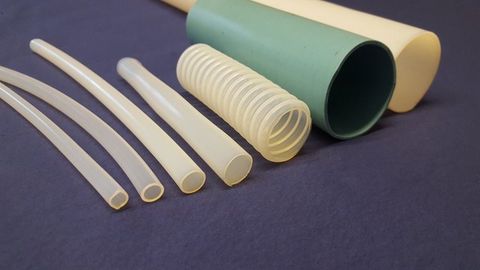

Paste extrusion is used in the PTFE production of thin tubes, thick tubes, wire insulations and unsintered PTFE tapes. For the PTFE paste extruder, only emulsion polymerization powder is used. The paste is a mixture of these spongy PTFE powder types with moistened organic liquids.

The extrusion direction can be done:

- Vertical upwards

- Vertical down

- Horizontal

- Additional directions

Advantages of the Keicher RAM extruder or PTFE extruder

- High tube concentricity due to patented system

- Small wall thickness tolerance

- High accuracy extrusion through additional speed control

- Measurement transducers such as pressure, force and speed for permanent control of the extrusion process

- Additional heatable extrusion nozzled for better extrusion quality

- Hydraulic closure with high closing force for quick loading of the extruder

- Quick loading with special loading carriage, also possible with several pro-forms, no manual touch

- Quick chargeable press cylinders

- Electrically adjustable mandrel

- Operation via touch screen and recording of extrusion parameters

- Safe operation date

- Automatic adjusting for extruder, preform and oven according to existing recipes

The process is carried out in batch quantities:

The PTFE lubricant mixture is first pre-pressed to so-called preforms and then filled into a PTFE paste extruder, which operates on the principle of stamp extrusion. Subsequently, the preform is pressed in cold or slightly preheated state through a cone nozzle. The extrudate is separated from the remaining lubricant within the drying zone and then sintered.

Sizes of PTFE paste extruder:

The PTFE paste extruder is available in different sizes.

The size is the maximum diameter of the preform.

- 50mm (2 ")

- 50 - 100mm (4")

- 100 - 150mm (6 ")

- 150 - 200mm (8")

- 200 - 250mm (10 ")

- 250 - 300 (12")

For additional information about our vertical RAM extruders, visit us on YouTube

Your direct contact

Should you require additional information about our products